Bypassing the low oil sensor on a generator is not difficult. Follow the right steps, and you can do it safely.

Generators have low oil sensors to prevent damage. Sometimes, these sensors malfunction, causing the generator to shut down even with enough oil. This can be frustrating, especially during critical power needs. If you understand the process, you can bypass the sensor easily.

This guide will show you the steps to bypass the low oil sensor. Remember, it’s important to handle this task with care to avoid engine damage. Let’s get started on how you can do this safely and efficiently.

Risks of Bypassing Sensors

Bypassing the low oil sensor on a generator might seem like a quick fix to keep it running. It’s important to understand the risks involved. The low oil sensor is a safety feature. Ignoring it can lead to significant problems.

Safety Hazards

Bypassing the low oil sensor can create several safety hazards. The sensor ensures the engine has enough oil. Without enough oil, the engine can overheat. Overheating can cause fires or even explosions. Here are some potential safety hazards:

- Overheating: Without the sensor, the engine might run without enough oil. This can cause it to overheat quickly.

- Fire Risk: An overheated engine can ignite fuel or oil. This can lead to a fire.

- Explosion: In extreme cases, overheating can cause parts to explode.

Ensuring oil levels are adequate is vital. This prevents overheating and reduces fire risk. It’s not worth the danger to bypass this important safety feature.

Potential Damage

Bypassing the low oil sensor can also cause severe damage to your generator. The sensor is there to protect the engine. Running the engine without enough oil can lead to permanent damage. Here are some potential damages:

- Engine Damage: Lack of oil can cause parts to grind against each other. This leads to wear and tear.

- Piston Damage: Insufficient oil can cause pistons to seize up. This can ruin the engine.

- Costly Repairs: Fixing an engine damaged by low oil can be expensive. It might even be cheaper to buy a new generator.

It’s crucial to maintain proper oil levels. The low oil sensor helps with this. Bypassing it can lead to costly repairs or the need for a replacement.

Tools Needed

When bypassing a low oil sensor on a generator, having the right tools is essential. Using the proper tools ensures a smooth process and reduces the risk of damaging your generator. This section will outline the basic tools and safety gear you need to safely bypass the low oil sensor.

Basic Tools

To bypass the low oil sensor on your generator, you will need several basic tools. These tools are common in most households and are easy to use. Here is a list of the tools you will need:

- Screwdrivers: Both flathead and Phillips head screwdrivers will be necessary for opening the generator’s casing and accessing the sensor.

- Wire Cutters: Essential for cutting and stripping wires connected to the sensor.

- Multimeter: Useful for checking electrical connections and ensuring the sensor is properly bypassed.

- Electrical Tape: Important for securing any exposed wires after bypassing the sensor.

- Wrench Set: Needed for loosening and tightening bolts within the generator.

Having these tools on hand will make the process quicker and easier. It’s important to ensure that each tool is in good condition to avoid any interruptions. Below is a table summarizing the tools needed:

| Tool | Purpose |

|---|---|

| Screwdrivers | Opening the casing and accessing the sensor |

| Wire Cutters | Cutting and stripping wires |

| Multimeter | Checking electrical connections |

| Electrical Tape | Securing exposed wires |

| Wrench Set | Loosening and tightening bolts |

Safety Gear

Safety should always be a top priority when working with generators. Proper safety gear can protect you from potential hazards. Here’s a list of essential safety gear for this task:

- Safety Glasses: Protects your eyes from debris and accidental splashes of oil or other fluids.

- Gloves: Essential for protecting your hands from sharp edges and hot surfaces.

- Ear Protection: Generators can be loud, and prolonged exposure can damage your hearing.

- Fire Extinguisher: Always have one nearby in case of accidental fires.

- Protective Clothing: Wear long sleeves and pants to protect your skin from burns and cuts.

Wearing the right safety gear is crucial to avoid injuries. Each piece of gear plays a specific role in keeping you safe:

| Safety Gear | Purpose |

|---|---|

| Safety Glasses | Eye protection from debris and fluids |

| Gloves | Hand protection from sharp edges and hot surfaces |

| Ear Protection | Hearing protection from loud noise |

| Fire Extinguisher | Emergency fire control |

| Protective Clothing | Skin protection from burns and cuts |

By ensuring you have the necessary basic tools and safety gear, you can bypass the low oil sensor on your generator effectively and safely.

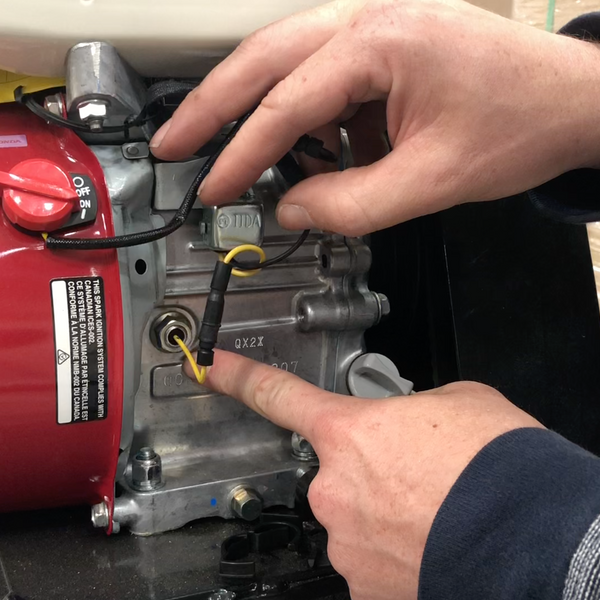

Identifying The Sensor

Generators are essential for providing backup power, especially during emergencies. However, sometimes the low oil sensor can cause issues, shutting down the generator even when oil levels are adequate. Identifying the sensor is the first step to bypassing it. This guide will help you locate the sensor and understand its wiring diagram, making the bypass process straightforward.

Location On Generator

Finding the low oil sensor on your generator is crucial. The sensor ensures the generator does not run with insufficient oil, potentially causing damage. Typically, the sensor is found near the engine’s oil reservoir.

Here are common locations:

- Near the oil dipstick: The sensor is often located close to where you check the oil level. Look for a small, wired device near the dipstick.

- On the engine block: Some generators have the sensor mounted directly on the engine block. Check around the base or sides of the engine.

- Below the oil fill cap: In some models, the sensor is positioned just below where you add oil. Inspect this area thoroughly.

Refer to your generator’s manual for the exact location. It typically includes diagrams showing where the low oil sensor is positioned. If you do not have the manual, a quick online search with your generator’s make and model should help.

Once you locate the sensor, take note of its connections. This will be important for the next step, which involves understanding the wiring diagram.

Wiring Diagram

The wiring diagram is essential for bypassing the low oil sensor. It shows how the sensor connects to the generator’s control board and engine.

Here’s a simple breakdown:

- Identify the sensor wires: Typically, two wires connect to the sensor. One is a ground wire, and the other is a signal wire.

- Trace the wires: Follow the wires from the sensor to the control board. This will help you understand the circuit path.

- Refer to the wiring diagram: The wiring diagram will show the connections clearly. Look for labels like “Low Oil Sensor” or “Oil Pressure Switch.”

Below is an example of a basic wiring diagram:

| Component | Wire Color | Connection Point |

|---|---|---|

| Low Oil Sensor | Yellow | Control Board Pin 3 |

| Ground Wire | Black | Engine Block |

| Signal Wire | Red | Control Board Pin 5 |

Carefully disconnect the sensor wires following the diagram. Connect the signal wire directly to the control board, bypassing the sensor. Ensure all connections are secure to avoid electrical issues.

Understanding the wiring diagram and the sensor’s location makes the bypass process manageable. Follow these steps to keep your generator running smoothly.

Bypassing Techniques

Generators are essential for providing backup power during outages. They ensure your home or business remains operational. Sometimes, the low oil sensor can cause the generator to shut down even if there is enough oil. In these situations, bypassing the low oil sensor can be a quick fix. This guide will explore some effective bypassing techniques to keep your generator running smoothly.

Manual Override

One common method to bypass the low oil sensor is the manual override. This technique involves a few straightforward steps:

- First, locate the low oil sensor on your generator. It is usually near the engine block.

- Next, identify the sensor wire. This wire connects the sensor to the generator’s control panel.

- Disconnect the sensor wire. This action will prevent the sensor from sending a low oil signal to the control panel.

- Ensure the generator has enough oil before starting it up. Running the generator without sufficient oil can cause severe damage.

By following these steps, you can manually override the low oil sensor and keep your generator running. Remember, this is a temporary solution. Regularly check and maintain oil levels to avoid long-term issues.

Wiring Modifications

Another method to bypass the low oil sensor is by making wiring modifications. This approach requires some basic knowledge of your generator’s electrical system:

- Start by turning off the generator and disconnecting it from any power sources. Safety first!

- Open the generator’s control panel to access the wiring. This step may require a screwdriver.

- Locate the wire that connects the low oil sensor to the control panel. It is usually labeled or color-coded.

- Cut the wire and strip the ends of both cut sections. Be careful to expose only a small length of the wire.

- Connect the two stripped ends using a wire nut or electrical tape. This connection will bypass the low oil sensor.

- Close the control panel and secure it with screws.

These wiring modifications create a permanent bypass for the low oil sensor. While effective, it’s crucial to monitor oil levels regularly. Neglecting oil maintenance can lead to engine damage.

By employing these bypassing techniques, you can ensure your generator operates without unnecessary shutdowns. Always prioritize safety and regular maintenance to extend the life of your generator.

Testing After Bypass

Bypassing the low oil sensor on a generator may seem like a quick fix. But it is crucial to ensure the generator runs smoothly afterward. Testing after bypass ensures the generator operates correctly and safely. This section covers two key aspects: functionality check and leak detection.

Functionality Check

After bypassing the low oil sensor, the first step is a functionality check. This step verifies the generator starts and runs without issues. Follow these steps:

- Turn on the generator.

- Listen for unusual noises.

- Check the control panel for error messages.

- Ensure the generator runs continuously for at least 15 minutes.

If the generator runs smoothly, proceed to test its performance under load. This involves connecting devices to the generator and observing if it handles the load without problems. Use a load tester if available. Here’s a simple table to help with the load testing process:

| Device | Wattage | Duration |

|---|---|---|

| Light Bulb | 60W | 5 minutes |

| Fan | 75W | 5 minutes |

| Refrigerator | 150W | 10 minutes |

Ensure all connected devices run without interruptions. If the generator handles these loads, it is likely functioning well. Remember, a functional generator should start easily, run smoothly, and handle expected loads.

Leak Detection

Leak detection is critical after bypassing the low oil sensor. Check for oil leaks to prevent damage or hazards. Follow these steps:

- Turn off the generator.

- Inspect the oil filter and oil lines for leaks.

- Check the oil pan and surrounding area.

- Look for oil spots on the ground under the generator.

Use a flashlight to inspect hard-to-see areas. If you find any leaks, tighten connections and replace damaged parts. Here’s a quick checklist for leak detection:

- Oil filter: Tighten or replace.

- Oil lines: Check for cracks or loose fittings.

- Oil pan: Inspect for damage or worn seals.

- Ground: Look for fresh oil spots.

Proper leak detection keeps your generator safe and efficient. Fixing leaks promptly can prevent major issues. Always keep an eye on the oil level and condition. Regular checks ensure the generator remains in good working order.

Credit: tomahawk-power.com

Common Issues Faced

Generators are handy machines, especially during power outages. They keep our homes and businesses running smoothly. But sometimes, the low oil sensor on a generator can cause problems. Understanding common issues faced while bypassing the low oil sensor can help you fix them easily. Let’s explore some of these issues.

Sensor Malfunction

One of the most frequent issues is sensor malfunction. A faulty sensor can cause unnecessary shutdowns. This can be frustrating, especially during critical times. Here are some common reasons for sensor malfunction:

- Wiring problems

- Dirty or clogged sensor

- Mechanical wear and tear

These issues can be easily resolved by:

- Checking the wiring connections. Ensure they are secure and free from damage.

- Cleaning the sensor. Dirt and oil buildup can affect its performance.

- Replacing the sensor. If it’s old or damaged, a new sensor might be necessary.

Here’s a simple troubleshooting table:

| Issue | Solution |

|---|---|

| Wiring problems | Inspect and secure connections |

| Dirty sensor | Clean the sensor |

| Old sensor | Replace the sensor |

Engine Performance

Another common issue is engine performance. A malfunctioning low oil sensor can affect how the engine runs. It can cause the engine to shut down unexpectedly. This can lead to more serious problems if not addressed.

Signs of engine performance issues include:

- Frequent shutdowns

- Unstable running

- Unusual noises

To improve engine performance, you can:

- Ensure proper oil levels. Regularly check and maintain the oil level in your generator.

- Perform routine maintenance. This includes changing the oil and filters as recommended by the manufacturer.

- Inspect the sensor and wiring. Make sure they are in good condition and functioning properly.

Here’s a quick reference table:

| Symptom | Action |

|---|---|

| Frequent shutdowns | Check oil level and sensor |

| Unstable running | Perform maintenance |

| Unusual noises | Inspect engine and wiring |

By understanding these common issues, you can keep your generator running smoothly. Regular maintenance and timely checks can prevent most problems, ensuring your generator is always ready when you need it.

Alternatives To Bypassing

Generators are essential during power outages. Sometimes, the low oil sensor can cause issues, leading to the need for bypassing. But bypassing the sensor may not be the safest or most effective solution. Instead, consider these alternatives to bypassing the low oil sensor for a smoother and safer operation.

Regular Maintenance

Regular maintenance is crucial for keeping your generator in top condition. It can prevent low oil sensor issues and extend the life of your generator. Here are some simple steps to follow:

- Check the oil level: Ensure the oil level is within the recommended range. Low oil levels can trigger the sensor.

- Change the oil: Regularly changing the oil keeps the engine running smoothly. Refer to the manufacturer’s guidelines for the correct oil change intervals.

- Clean the air filter: A clogged air filter can affect the engine’s performance. Clean or replace it as needed.

- Inspect spark plugs: Replace worn-out spark plugs to ensure efficient combustion and avoid sensor issues.

- Check the battery: A weak battery can cause starting problems. Keep it charged and clean the terminals.

| Maintenance Task | Frequency |

|---|---|

| Check oil level | Before each use |

| Change oil | Every 50-100 hours |

| Clean air filter | Every 100 hours |

| Inspect spark plugs | Annually |

| Check battery | Monthly |

Following a regular maintenance schedule can prevent many common generator issues, including those related to the low oil sensor.

Sensor Replacement

Sometimes, the low oil sensor itself can be faulty. Replacing the sensor can be a straightforward solution. Here’s a simple guide to help you through the process:

- Identify the sensor: Locate the low oil sensor on your generator. Refer to the user manual for its exact position.

- Disconnect the power: Ensure the generator is turned off and disconnect the battery to avoid any electrical hazards.

- Remove the old sensor: Carefully disconnect the wires connected to the sensor. Use a wrench to unscrew and remove the sensor.

- Install the new sensor: Place the new sensor in the same position and screw it in securely. Reconnect the wires as they were.

- Reconnect the power: Reconnect the battery and turn on the generator to test the new sensor.

Replacing the sensor can resolve issues without bypassing it. It’s a safer option that ensures your generator continues to operate effectively.

By following these alternatives, you can maintain a functional and safe generator without the need to bypass the low oil sensor. Regular maintenance and sensor replacement are both effective ways to keep your generator running smoothly.

Credit: www.youtube.com

Legal And Warranty Considerations

Introduction paragraph about How to Bypass Low Oil Sensor on Generator Easily? and Legal and Warranty Considerations…

Manufacturer Policies

Before bypassing the low oil sensor on your generator, understand the manufacturer’s policies. Tampering with the sensor may void your warranty. Most manufacturers include a clause in their warranty terms that states any modification to the generator, including bypassing safety features, will result in loss of warranty coverage.

Review the user manual or warranty documentation to find specific details. Look for sections that mention modifications, tampering, or unauthorized repairs.

- Warranty voiding: Bypassing the sensor typically voids the warranty.

- Safety risks: Manufacturers emphasize that the low oil sensor is a critical safety feature.

- Repair policies: Many manufacturers will refuse to repair generators that have been tampered with.

Consider contacting customer support to ask about the implications of bypassing the sensor. They may offer solutions that don’t involve bypassing the sensor, preserving your warranty and ensuring safety.

Here is a sample table summarizing potential consequences:

| Action | Potential Consequence |

|---|---|

| Bypassing the Sensor | Warranty Void |

| Unauthorized Repairs | Denial of Service |

| Contacting Support | Possible Alternative Solutions |

Local Regulations

Bypassing the low oil sensor on your generator may also conflict with local regulations. Different regions have laws regarding the modification of safety features on machinery. These laws are in place to ensure the safe operation of equipment and to protect users from potential hazards.

Research the regulations in your area before making any modifications. Here are some steps to help you understand local laws:

- Check local government websites: They often have sections on machinery safety regulations.

- Contact local safety authorities: Get in touch with agencies that oversee equipment safety.

- Consult with professionals: Ask technicians or experts about the legal implications of bypassing safety features.

Ignoring local regulations can lead to fines, legal issues, and increased safety risks. Here is a brief overview:

| Regulation | Possible Outcome |

|---|---|

| Safety Modification Laws | Fines or Legal Action |

| Equipment Safety Standards | Increased Safety Risks |

| Professional Guidelines | Expert Advice and Compliance |

Following local regulations ensures you remain compliant with the law and maintain safe operation of your generator.

Credit: www.generatormechanics.com

Frequently Asked Questions

Can You Drive Without An Oil Level Sensor?

Yes, you can drive without an oil level sensor. Regularly check your oil level manually to avoid engine damage.

How Do I Reset The Oil Level Sensor?

To reset the oil level sensor, turn the ignition on without starting the engine. Press the accelerator three times within 10 seconds. Turn off the ignition, then start the engine. The sensor should be reset.

How To Reset A Low Oil Pressure Sensor?

Turn off the engine and disconnect the battery. Locate the sensor, unplug it, and clean the area. Reconnect it and reset the vehicle’s computer by reconnecting the battery.

How To Fix Low Oil Pressure In Generator?

Check the oil level and add oil if needed. Replace the oil filter if it’s clogged. Inspect for oil leaks and fix them. Ensure the oil pump functions properly.

Why Would You Bypass A Low Oil Sensor On A Generator?

A low oil sensor can malfunction and falsely shut down your generator.

Is It Safe To Bypass A Low Oil Sensor On A Generator?

It is not safe. It can damage your generator if oil levels are really low.

How Do I Know If My Oil Sensor Is Faulty?

If your generator shuts down despite having enough oil, the sensor might be faulty.

What Tools Do I Need To Bypass The Low Oil Sensor?

You will need a wire cutter, electrical tape, and possibly a screwdriver.

Conclusion

Bypassing a low oil sensor on a generator can be simple. Always prioritize safety and follow instructions carefully. This guide provides straightforward steps to help you. Regular maintenance ensures your generator runs smoothly. Proper care extends its lifespan and efficiency.

Remember to check oil levels frequently. This prevents damage and unexpected shutdowns. Stay informed and keep your generator in top condition.